- Home

- Pipe

- Tube

- 304 stainless steel tube

- 304L stainless steel tube

- 316L stainless steel tube

- 310S stainless steel tube

- 321 stainless steel tube

- 201 stainless steel tube

- 201H stainless steel tube

- 409L stainless steel tube

- 430 stainless steel tube

- 439 stainless steel tube

- 441 stainless steel tube

- 2205 stainless steel tube

- 2507 stainless steel tube

- Stainless steel round tube

- Stainless steel square tube

- Stainless steel rectangular tube

- Stainless steel oval tube

- Stainless steel slot tube

- Stainless steel sanitary tube

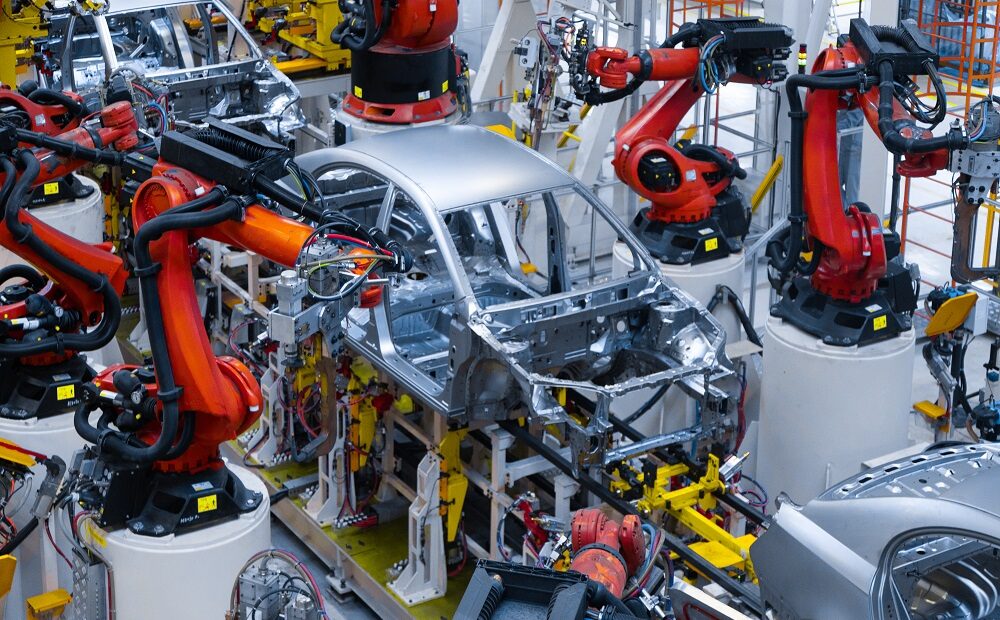

- Stainless steel exhaust tube

- Stainless steel heat exchanger tube

- Perforated stainless steel tube

- Stainless steel handrail tube

- Stainless steel pressure tube

- Polished stainless steel tube

- Thin wall stainless steel tube

- 25mm stainless steel tube

- 22mm stainless steel tube

- 12mm stainless steel tube

- 1 inch stainless steel tube

- 2 inch stainless steel tube

- 2×2 stainless steel tube

- 3/8 stainless steel tube

- 4 diameter stainless steel tube

- Stainless Grades

- Standards

- Industry

- About Us

- Calculator

- Contact Us