ASTM A249 and A269 standards specify requirements for stainless steel welded tubes in distillation column applications:

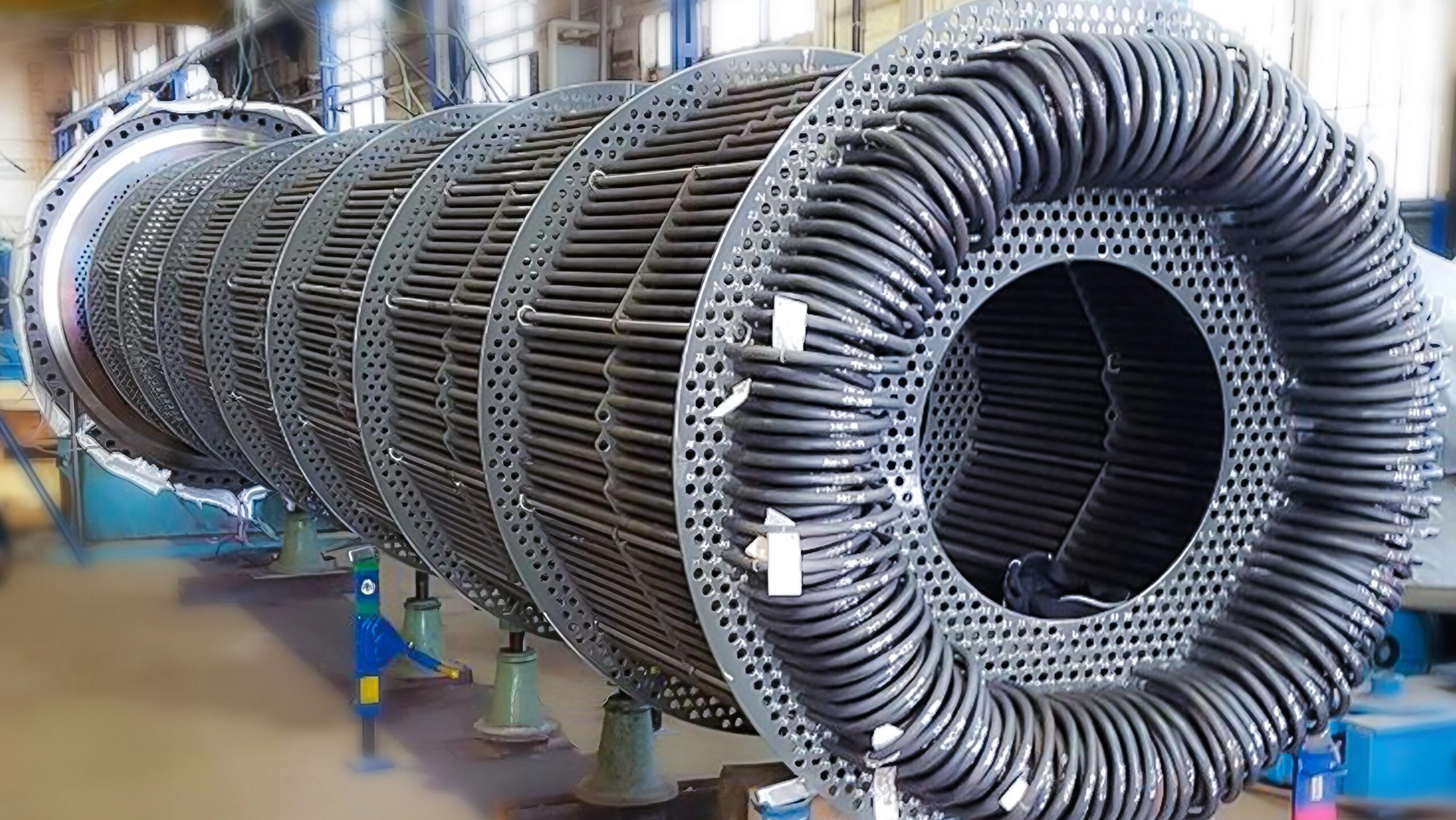

ASTM A249 is designed for welded austenitic tubes in high-temperature environments, requiring an automatic welding process, post-weld heat treatment, and comprehensive mechanical and nondestructive testing. These tubes are ideal for parts of distillation columns, including reboilers and condensers, where high temperature and structural integrity are critical.

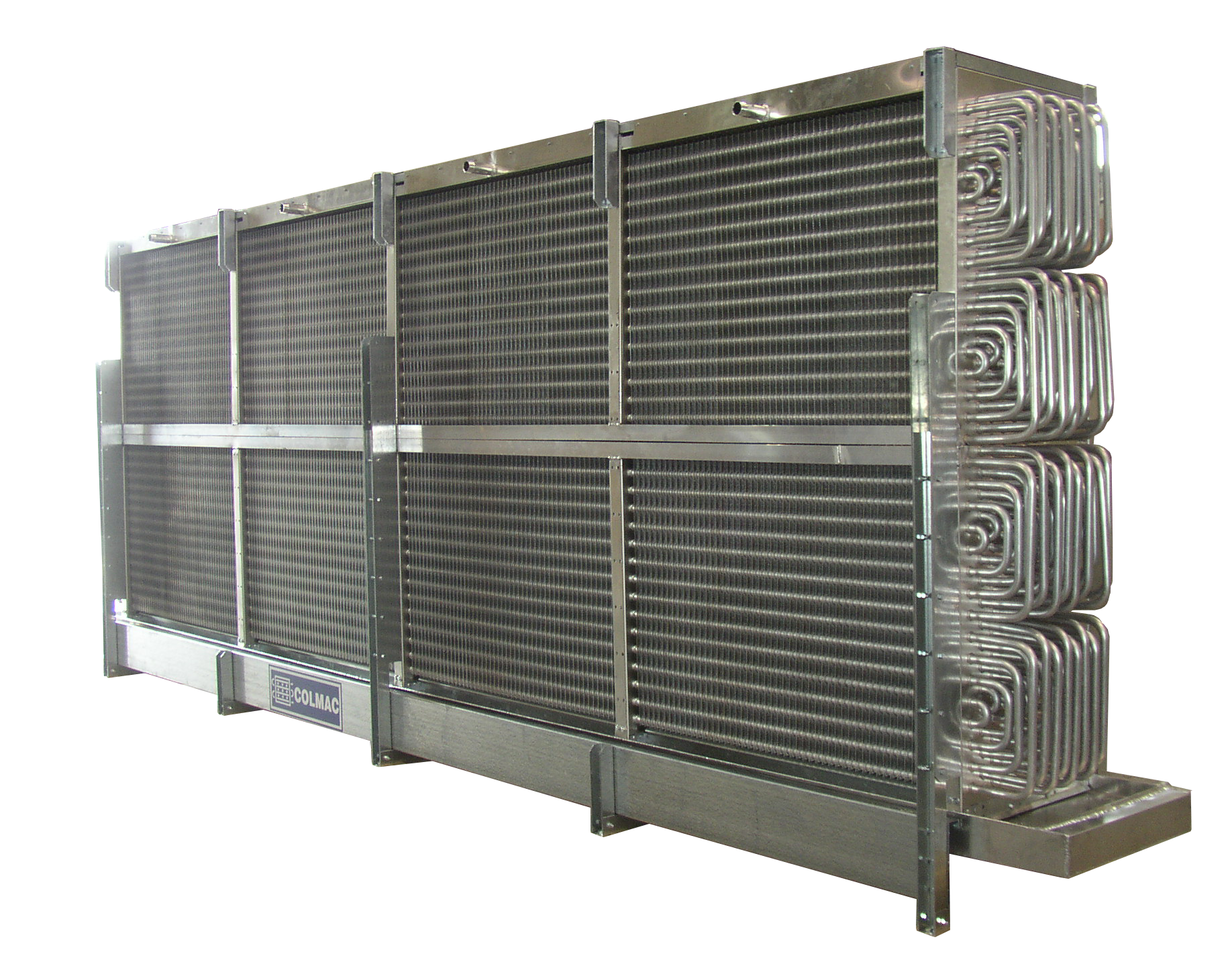

ASTM A269 covers both seamless and welded austenitic stainless steel tubing with an emphasis on corrosion resistance, suitable for less extreme temperature and pressure conditions in distillation processes. Tubes must pass thermal treatment and nondestructive tests to ensure quality and corrosion resistance.

Choosing between ASTM A249 and A269 for distillation columns hinges on process-specific factors like temperature, pressure, and corrosive exposure. ASTM A249 tubes are preferable for high-temperature zones, whereas ASTM A269 tubes are adequate for areas where corrosion resistance is the priority.