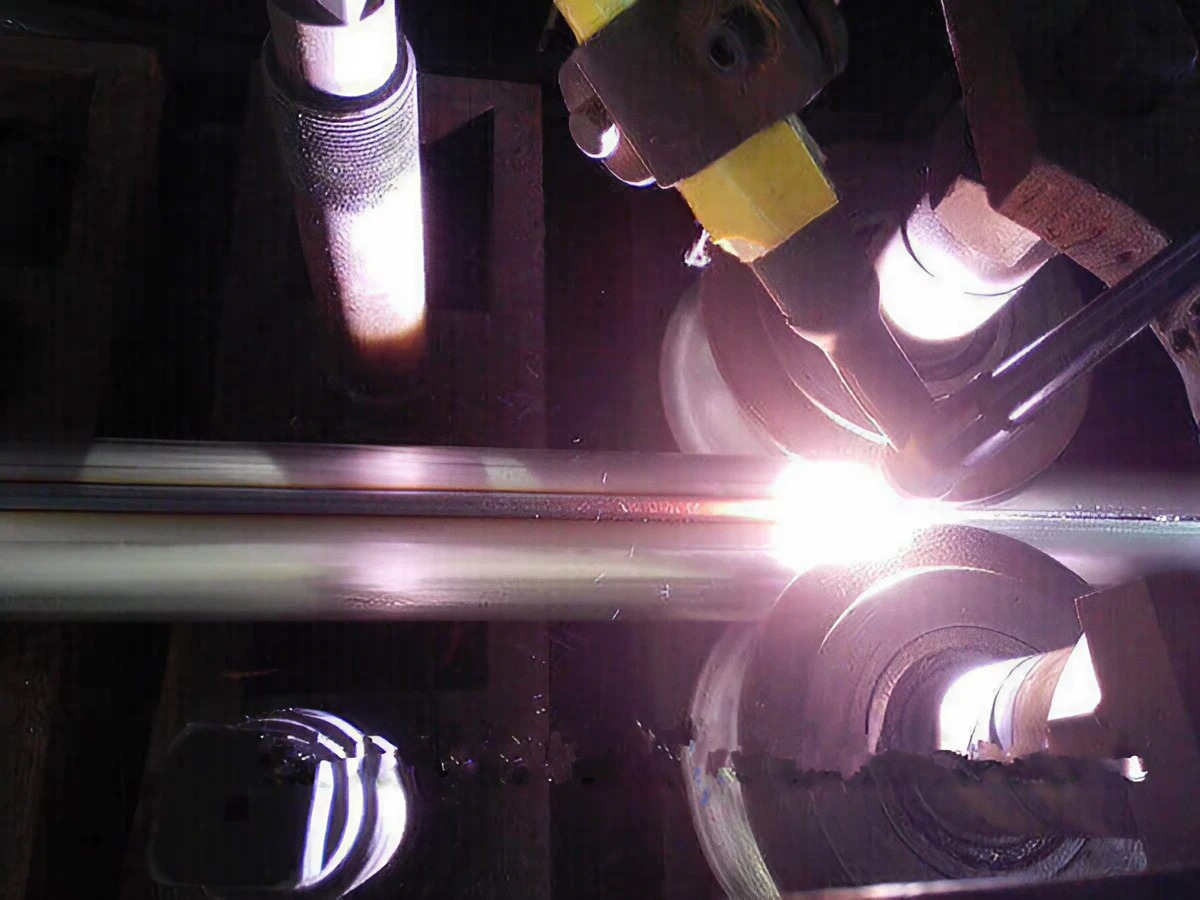

TIG WELDING

TIG welding is a preferred method for welding stainless steel tubes / stainless steel pipes because it produces high-quality, clean welds with minimal distortion, discoloration, or contamination. To ensure successful TIG welding of stainless steel tubes / stainless steel pipes, it is essential to properly prepare the surface by cleaning and removing any oxides, using appropriate fixtures to hold the tube in place, selecting the right filler material, and controlling the heat input during the welding process. Additionally, selecting the right welding parameters, including current, voltage, and travel speed, is critical to achieving a strong and reliable weld.

PLASMA WELDING

Stainless steel tube / stainless steel pipe plasma welding offers several advantages over other welding processes. It provides high-quality, precise welds that are free of defects and contamination while producing minimal distortion and warping. Additionally, plasma welding allows for higher welding speeds and deeper penetration, making it suitable for thicker materials than traditional TIG welding.

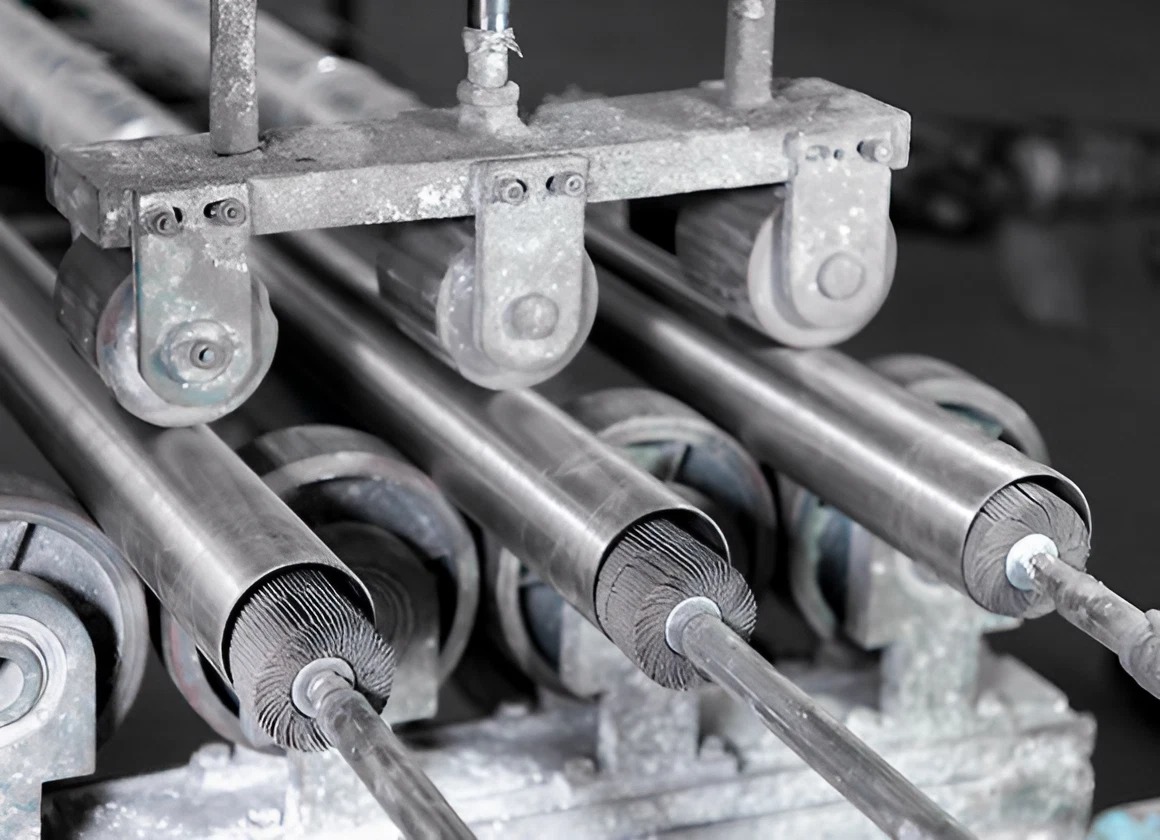

OUTER POLISHING

Mechanical outer polishing is a surface treatment method that removes defects and obtains a smooth surface on stainless steel tubes / stainless steel pipes by applying force to the surface. Materials used in mechanical polishing include sandpaper, flat polishing wheels, and abrasive sticks. Mechanical polishing improves the quality and corrosion resistance of the stainless steel tube / stainless steel pipe surface and makes it easier to clean and maintain.

INNER POLISHING

Mechanical inner polishing of stainless steel tubes / stainless steel pipes involves the use of specialized polishing tools and abrasive materials to remove any roughness or defects from the inside surfaces of the tubes. The polishing process smoothens the inner surfaces, making it easier for liquids or gases to pass through without being impeded by roughness or irregularities in the surface. The process involves placing a specialized rotary polishing tool into the tube and then moving it back and forth along the length of the tube until the desired level of smoothness is achieved. This process is commonly used in industries such as food processing, pharmaceuticals, and semiconductors where cleanliness and smoothness of the inner surfaces are critical to ensure product quality and safety.

BRIGHT ANNEALING

Bright annealing is a heat treatment process used to remove impurities and improve the surface finish of stainless steel tubes / stainless steel pipes. The bright annealing process also increases the ductility and corrosion resistance of stainless steel tubes / stainless steel pipes, making them suitable for use in high-temperature and corrosive environments. After annealing, the tubes are quenched in water or air to cool them down rapidly and then polished or buffed to achieve a shiny, reflective surface. Bright annealed stainless steel tubes are commonly used in industries like aerospace, medical, and semiconductor manufacturing where high-quality finishes and exceptional performance are essential.

BEAD REMOVING

Stainless steel tube / stainless steel pipe bead removing is the process of removing excess weld material, or "bead," from the surface of the tube after it has been welded. The bead is created during the welding process and can be unsightly, create a rough surface, and even cause issues during subsequent processing or use. The goal of bead removal is to create a clean, smooth surface that meets required standards and specifications. The bead removal process is critical in industries such as food processing, pharmaceuticals, and semiconductor manufacturing, where surface quality and cleanliness are essential. Failure to remove the bead adequately can lead to product contamination, equipment damage, and potential safety hazards.

PICKLING

Stainless steel tube / stainless steel pipe pickling is a surface treatment process used to remove corrosion and weld damage from stainless steel surfaces. The process involves immersing the stainless steel tube / stainless steel pipe in an acid solution, typically hydrochloric or sulfuric acid, to remove oxide scale and heat tint while dissolving steel flecks embedded in the surface. Pickling is commonly employed in industries that involve exposure to corrosive environments, such as chemical processing, oil and gas, and pharmaceuticals. The process can improve the surface finish of stainless steel tubes / stainless steel pipes, making them more resistant to discoloration, rust, and other forms of corrosion. It can also prepare the stainless steel surface for subsequent treatments, such as electropolishing or passivation, to enhance the corrosion resistance and aesthetic appeal of the finished product.

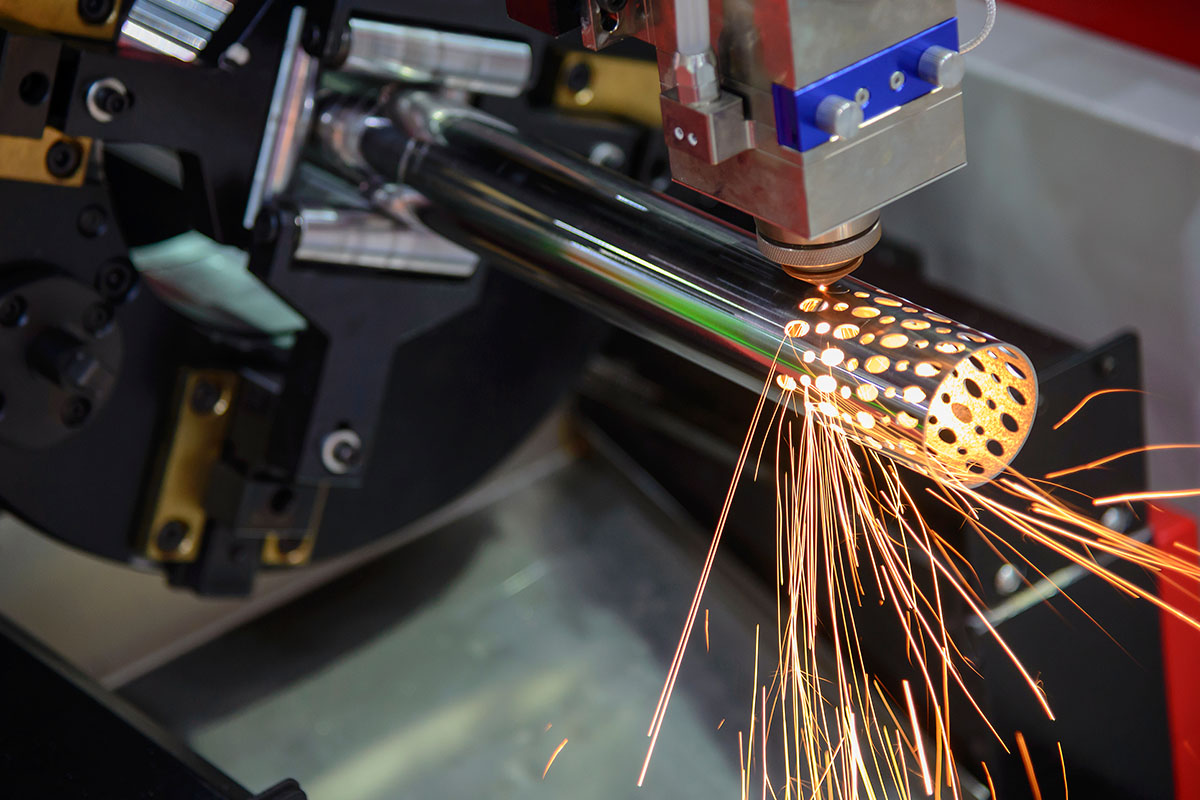

LASER CUTTING

Stainless steel tube laser cutting / stainless steel pipes laser cutting is a precise and efficient process used to cut complex shapes and designs into stainless steel tubing / stainless steel piping using a high-powered laser. The laser cutting machines are equipped with advanced software that can create complex designs and patterns with a high degree of precision, speed, and accuracy.It can also drill holes and add other features to the tube, making it a versatile and efficient process that saves time and reduces costs. Laser-cut tubes often require minimal clean-up or finishing work, which reduces labor costs and increases production efficiency. Overall, stainless steel tube laser cutting is a popular choice for manufacturers who require precise and intricate cuts on their stainless steel tubing. It is an advanced technology that provides superior quality and accuracy when compared to traditional cutting methods.

PERFORATING

Stainless steel tube perforating / stainless steel pipe perforating is the process of punching or drilling holes through a stainless steel tube to create a pattern or design. The holes can be made in various sizes and shapes, depending on the desired application. Perforated stainless steel tubes / stainless steel pipes are widely used in applications such as filtration, ventilation, and decorative purposes. Perforated tubes are commonly used in filtration applications, including air and liquid filtration in industries like food and beverage, petrochemicals, and water treatment. They can also be used as decorative elements in architectural and design applications.

Perforated stainless steel tubes / stainless steel pipes are valued for their strength, durability, and corrosion resistance, making them suitable for use in various harsh environments. They offer high precision, consistency, and repeatability, making them an ideal choice for applications that require precise hole placement and size.

Perforated stainless steel tubes / stainless steel pipes are valued for their strength, durability, and corrosion resistance, making them suitable for use in various harsh environments. They offer high precision, consistency, and repeatability, making them an ideal choice for applications that require precise hole placement and size.