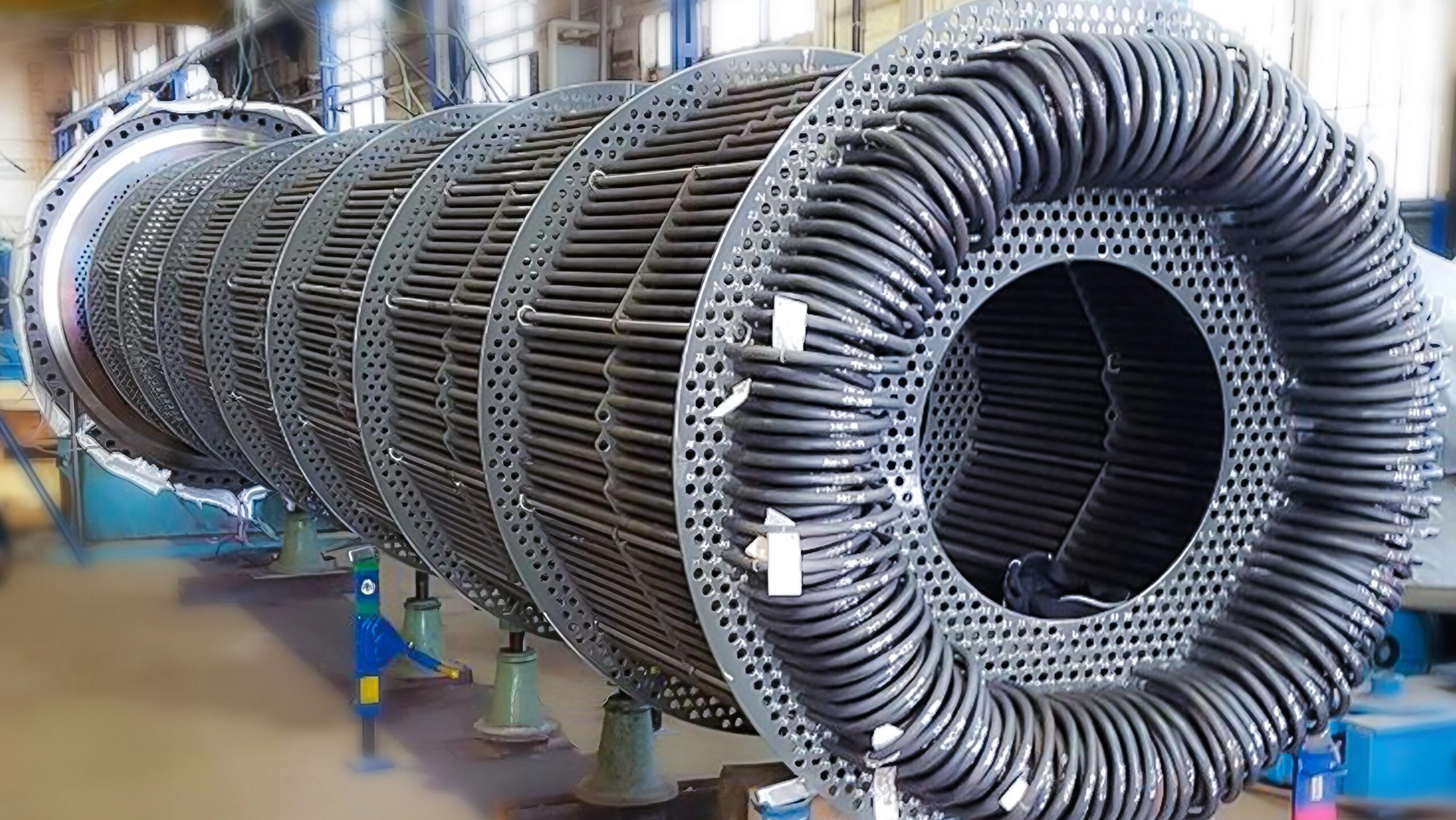

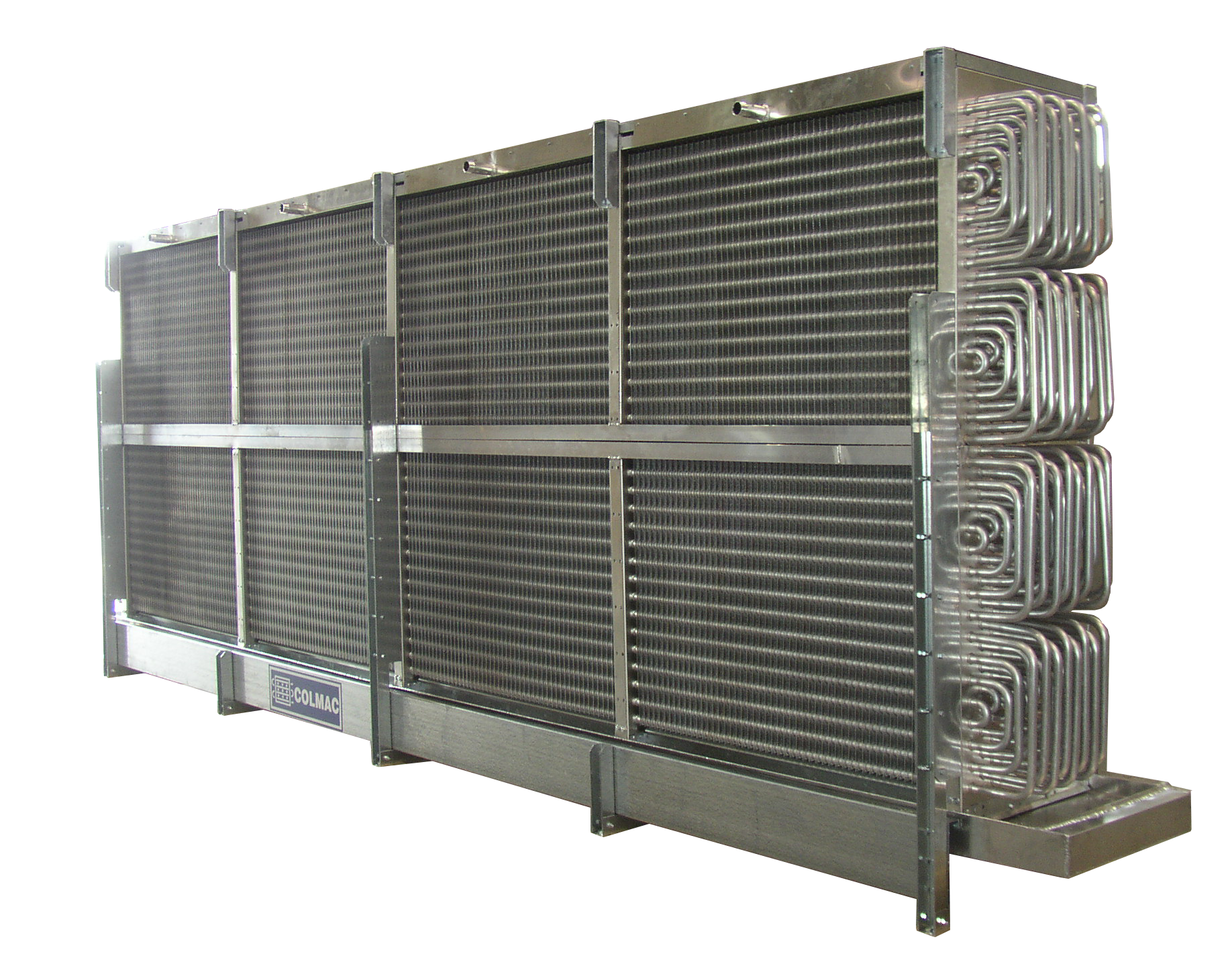

ASTM A789 stainless steel tubes are duplex stainless steel tubes, which means they have a two-phase microstructure consisting of grains of both austenitic and ferritic stainless steel. This duplex structure gives these tubes enhanced strength and resistance to stress corrosion cracking compared to regular austenitic or ferritic grades. In the context of boiler applications, ASTM A789 stainless steel tubes are used for their:

High Thermal Conductivity: Effective heat transfer is a critical aspect of boiler performance, and the thermal conductivity of duplex stainless steel is higher than that of austenitic grades, aiding in efficient heat exchange.

Corrosion Resistance: Boilers are environments where corrosion resistance is crucial due to constant exposure to water and high temperatures. The chromium and molybdenum content in ASTM A789 tubes provide excellent resistance to pitting and crevice corrosion.

Strength: The duplex structure provides high strength, allowing for thinner wall tubes that can withstand high pressure. This is especially important in high-pressure boiler applications.

Durability: The enhanced strength and corrosion resistance contribute to the long service life of boilers, reducing maintenance and replacement costs.

Temperature Resistance: These tubes can withstand high temperatures without losing their mechanical properties, making them suitable for the thermal stresses encountered in boilers.

In summary, the use of ASTM A789 stainless steel tubes in boilers allows for the construction of highly efficient, durable, and reliable systems that perform well under corrosive and high-pressure conditions, withstanding the harsh operational realities of modern boiler systems.